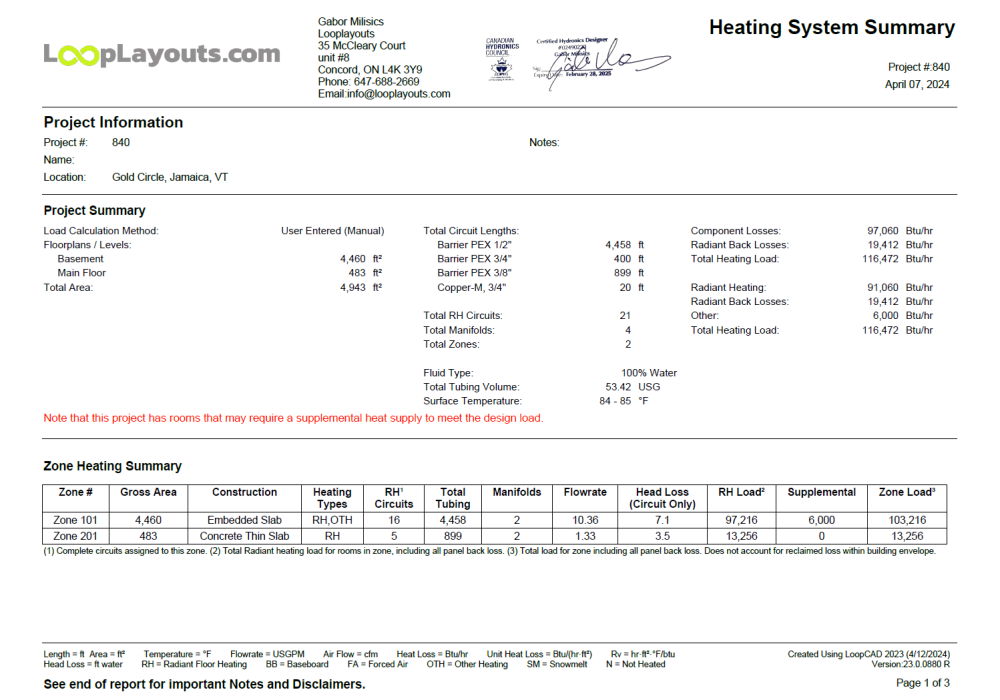

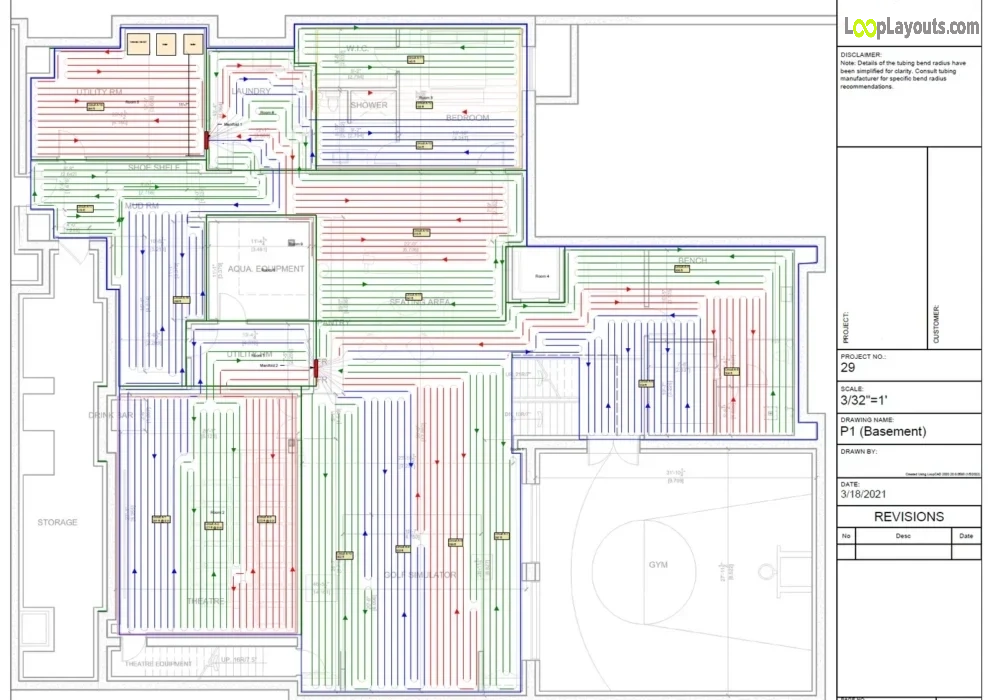

LoopCAD

Springel Homes

April 5, 2024

Jamaica, VT, USA

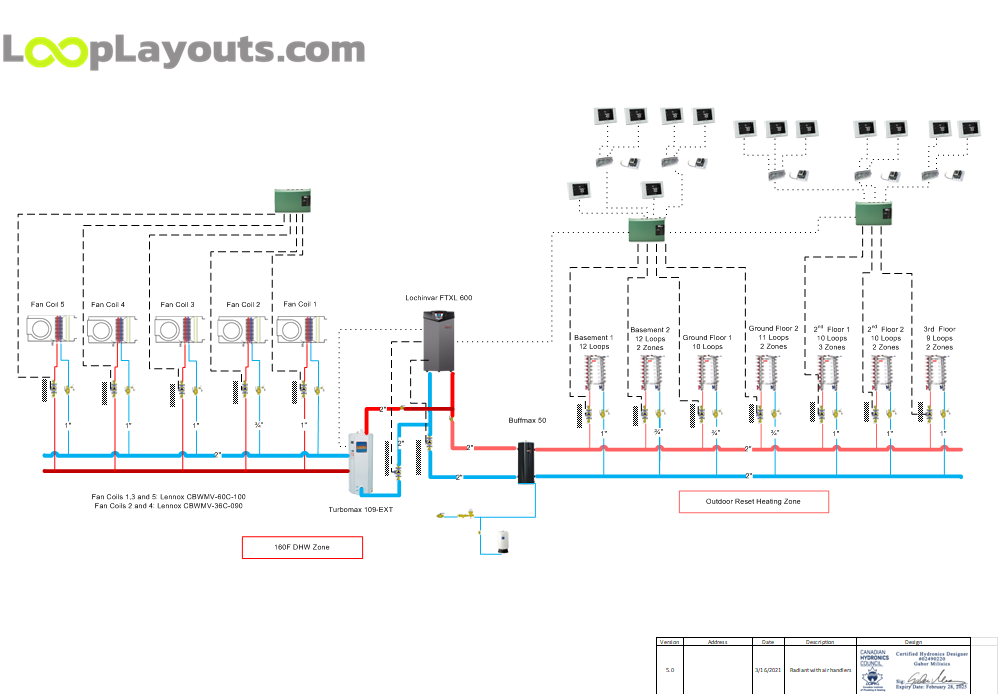

Canadian Hydronics Council Certified and stamped loop layout drawing, heat loss calculation and mechanical design package for building permits. All drawings and calculations needed to draw a residential building permit based on radiant floor heating being the primary source of heat. Does NOT include forced air and ventilation calculations nor duct layout drawings.

Detailed

Brad McCollough

June 5, 2023

Aspen, CO, USA

You will receive a list of all major components that the installer will need to supply to implement our design. If you have a preference for boilers, indirect tanks or such we will generate our design and list of components accordingly.

CAD Assisted

Eli Strauss

April 15, 2023

Aspen Colorado

Realistic

Nicolas Marko

March 1, 2021

24 Fifth st.,Los Angeles, USA